Hydra Push Spreader

No Limitations

The Hydra-Push Spreader does not limit farmers’ capabilities. Spreading cow manure is the key application but other alternative uses exist. Some uses that you may have never thought of:

- Wood Chips

- Orange Peels

- Soy Beans

- Saw Dust

- Pig Manure

- Turkey Manure

- Chicken Manure

- Sheep Manure

Twin Synchronized Beaters

Shred and fling material with maximum force for wide, even distribution.

Handles Heavy Material

Best for pen-packed, clumpy, or dense manure that needs complete breakup.

Adjustable Spread Widths

Deflectors quickly adjust to deliver patterns over 40 feet (12 metres).

Broad, Uniform Coverage

Covers large open fields efficiently with a consistent spread pattern.

Dual-stepped Beaters

Break down tough loads for a finer, more uniform spread pattern every time.

Precision Application

Ideal for dry to semi-solid manure, delivering accurate placement where it’s needed.

Long-Lasting Paddles

Made from heavy-duty steel, the paddles are reversible and replaceable for longer life.

Wide, Controlled Coverage

Provides a broad yet focused distribution, perfect for

row-crop operations.

Horizontal Beaters

- Dual-stepped beaters break up material for an even, fine spread pattern.

- Ideal for dry to semi-solid manure or applications requiring precise placement.

- Features reversible, replaceable paddles for long-lasting performance.

- Delivers a wide but focused spread — great for row-crop operations.

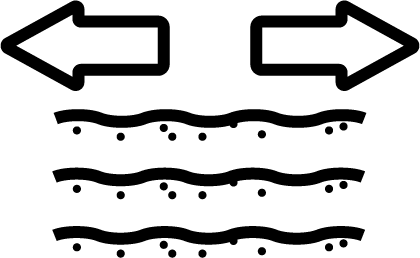

Vertical Beaters

- Twin synchronized beaters shred and fling material for maximum distribution.

- Best for pen-packed, heavy, or clumpy material that needs full breakup.

- Adjustable deflectors offer spreading widths over 40 feet (12 metres).

- Provides a broad, uniform pattern — perfect for open fields and bulk coverage.

Durability

Solid Poly Box Construction

Corrosion-proof, full-thickness poly panels on the floor and walls resist warping, freezing, and buildup in all seasons.

Wide Flotation Tires

Commercial-grade tires give superior ground clearance and stability, even in wet or uneven conditions.

Replaceable & Reversible Paddles

Built from ½” wear-resistant steel and designed to reverse for double the life and sustained spreading performance.

Epoxy Primer & Urethane Top Coat

Tough, baked-on paint resists rust, fading, and chips — plus optional custom colours to match your equipment.

Built To Last

From cast hubs to triple-lip bearings, every part of the Implemax Hydra Push Spreader is engineered for durability, uptime, and long-term ROI.

Performance

Hydraulic Push-Off Technology

Eliminates chains and slats for a smoother, more reliable unloading experience — even in the toughest conditions.

Heavy-Duty Beater System

Dual-stepped beaters (horizontal) or synchronized vertical beaters deliver smooth, uniform spreading across wide widths.

PTO Driveline with Overload Protection

Standard driveline includes triple-sealed bearings, eccentric locking collars, and slip protection for smooth, safe power delivery.

Variable Flow Control

Regulates unloading speed from 0 to 8 feet per minute to match the material and the job — fine-tuned performance at your fingertips.

Model Specifications

Specifications & Features | Dual Horizontal Beater Models | Dual Vertical Beater Models | ||||||

|---|---|---|---|---|---|---|---|---|

MODELS | H425 | H575 | H655 | H755 | V425 | V575 | V655 | V755 |

Heaped Capacity (Bushels) | 425 | 575 | 655 | 755 | 425 | 575 | 655 | 755 |

Heaped Capacity (ft3) | 530 | 720 | 820 | 940 | 530 | 720 | 820 | 940 |

Heaped Capacity (m3) | 15.4 | 20.3 | 23.1 | 26.6 | 15.4 | 20.3 | 23.1 | 26.6 |

Struck Level Capacity (ft3 / m3) | 272 / 7.7 | 408 / 11.6 | 431 / 12.2 | 481 / 13.6 | 272 / 7.7 | 408 / 11.6 | 431 / 12.2 | 481 / 13.6 |

Standard PTO Drive – RPM | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

Tractor Horsepower Requirements | 120 | 140 | 150 | 160 | 120 | 140 | 150 | 160 |

DUAL HORIZONTAL BEATERS | ||||||||

Main Beater (in / cm) | 24 / 61 | 26 / 66 | 26 / 66 | 26 / 66 | – | – | – | – |

Upper Beater (in / cm) | 16 / 41 | 26 / 66 | 22 / 56 | 26 / 66 | – | – | – | – |

Dual Vertical Beater Diameter (in / cm) | – | – | – | – | 36 / 91.5 | 36 / 91.5 | 42 / 106.5 | 42 / 106.5 |

Adjustable Spread Range to (ft / m) | – | – | – | – | 40 / 12 | 40 / 12 | 40 / 12 | 40 / 12 |

FLOTATION TIRE SIZE | ||||||||

Tire Size (R22.5) | 550 / 45 | 550 / 45 | 600 / 50 | 600 / 50 | 550 / 45 | 550 / 45 | 600 / 50 | 600 / 50 |

Inside Width (in / cm) | 68 / 173 | 68 / 173 | 80 / 203 | 80 / 203 | 68 / 173 | 68 / 173 | 80 / 203 | 80 / 203 |

Inside Length (in / cm) | 192 / 488 | 192 / 488 | 192 / 488 | 192 / 488 | 192 / 488 | 192 / 488 | 192 / 488 | 192 / 488 |

Inside Depth (in / cm) | 37 / 94 | 54 / 137 | 47 / 119 | 54 / 137 | 37 / 94 | 54 / 137 | 47 / 119 | 54 / 137 |

Overall Width with STD Tires | 120 / 305 | 120 / 305 | 132 / 335 | 132 / 335 | 120 / 305 | 120 / 305 | 132 / 335 | 132 / 335 |

Overall Length (in / cm) | 321 / 815 | 321 / 815 | 321 / 815 | 321 / 815 | 336 / 853 | 336 / 853 | 336 / 853 | 336 / 853 |

Overall Length (ft / m) | 26’9″ / 8.15 | 26’9″ / 8.15 | 26’9″ / 8.15 | 26’9″ / 8.15 | 28’0″ / 8.53 | 28’0″ / 8.53 | 28’0″ / 8.53 | 28’0″ / 8.53 |

Box Height with Side Rail Guards (in / cm) | 69 / 175 | 81 / 206 | 76 / 193 | 81 / 206 | 69 / 175 | 81 / 206 | 76 / 193 | 81 / 206 |

Overall Maximum Height (in / cm) | 75 / 191 | 82 / 216 | 83 / 211 | 85 / 216 | 108 / 274 | 120 / 305 | 115 / 292 | 120 / 305 |

Weight – Empty (lbs / kg) | 7,275 / 3,300 | 8,775 / 3,980 | 10,775 / 4,890 | 11,275 / 5,115 | 8,675 / 3,935 | 10,275 / 4,660 | 12,375 / 5,615 | 12,875 / 5,840 |

Max Loaded (lbs / kg) | 25,250 / 11,450 | 34,250 / 15,535 | 37,250 / 16,900 | 39,250 / 17,805 | 26,650 / 12,085 | 35,750 / 16,215 | 28,850 / 17,625 | 39,250 / 17,805 |

Push Off Cylinder Diameter (in) | 3.0/3.5 | 3.5/4.0 | 4.0/4.5 | 4.0/4.5 | 3.0/3.5 | 3.5/4.0 | 4.0/4.5 | 4.0/4.5 |

Replaceable Beater Paddles | ||||||||

Axle Assembly | Tandem | Tandem | Tandem | Tandem | Tandem | Tandem | Tandem | Tandem |

Hub | 10 Bolt | 10 Bolt | 10 Bolt | 10 Bolt | 10 Bolt | 10 Bolt | 10 Bolt | 10 Bolt |

Spindle Size (in) | 3 1/8 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/8 | 3 1/2 | 3 1/2 | 3 1/2 |

Hydraulic Ejection Unloading Speed | to 8 ft/min | to 8 ft/min | to 6 ft/min | to 6 ft/min | to 8 ft/min | to 8 ft/min | to 6 ft/min | to 6 ft/min |

Auto Gate – Automatic Rear Gate Opener | Std | Std | Std | Std | Std | Std | Std | Std |

Wood Side Rail Guards | Std | Std | Std | Std | Std | Std | Std | Std |

Slurry Pan | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

Swing Away Parking Jack | Std | Std | Std | Std | Std | Std | Std | Std |

Poly Box Liner Thickness (in / cm) | 1 / 2.54 | 1 / 2.54 | 1 / 2.54 | 1 / 2.54 | 1 / 2.54 | 1 / 2.54 | 1 / 2.54 | 1 / 2.54 |

Replaceable Sheet Liners | Std | Std | Std | Std | Std | Std | Std | Std |

Epoxy Primer & Urethane Top Coat | Std | Std | Std | Std | Std | Std | Std | Std |

*MODELS AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE